In recent years, the challenge of timely and accurate diagnosis has been significant, especially for critical conditions like cancer where early detection is crucial. The advent of Artificial Intelligence (AI) has opened new avenues to address these diagnostic challenges, ushering in a realm of solutions to enhance precision and efficiency in diagnostics. Among the emerging solutions, platforms like Google’s Vertex AI are hinting at the potential to further support healthcare professionals in tackling diagnostic hurdles.

Why Healthcare Diagnostics Need Improvement?

Traditionally, diagnostic processes have been a meticulous endeavor, often requiring exhaustive analysis and significant time investment. From the initial consultation to laboratory tests, imaging, and finally, a diagnostic conclusion, the journey is extensive. The stakes are high, with any misstep potentially leading to misdiagnoses, delayed treatment, and in grave instances, loss of life. The exigency for accuracy often dances on the razor’s edge with the pressing demand for promptness.

Despite the monumental advancements in medical technology over the decades, the core diagnostic process has remained relatively unchanged. A case in point is the diagnostic pathway of cancer, where the conventional route entails a series of steps including physical examinations, laboratory tests, biopsies, and imaging studies. Each phase is crucial, yet the cumulative time and resources expended are substantial.

The burgeoning global population and the concomitant rise in chronic diseases have further strained the efficiency and effectiveness of this model. The traditional diagnostic model is inching closer to its tipping point, beckoning a radical reformation to meet the exigencies of modern healthcare.

As we transition into a new era of medical diagnostics, AI and machine learning (ML) are emerging as powerful tools. They offer the potential to significantly improve the accuracy, speed, and cost-effectiveness of diagnostic procedures.

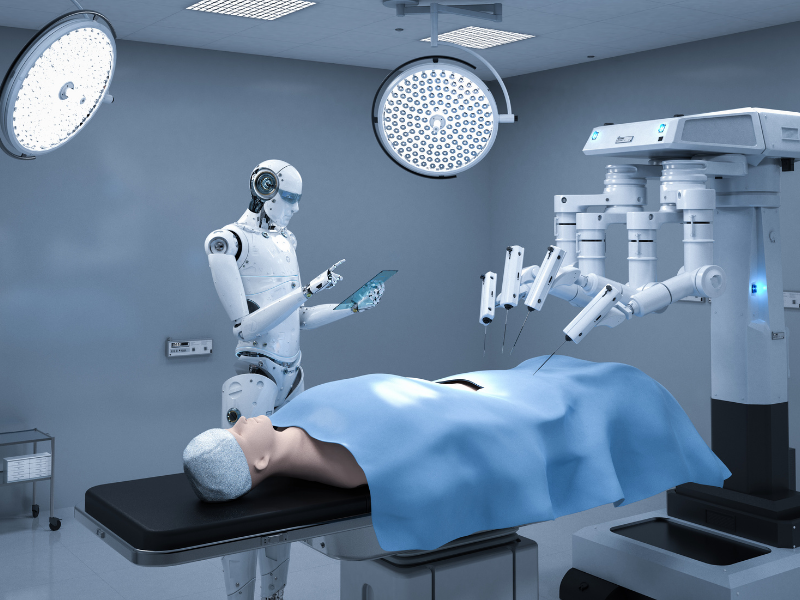

AI in Diagnostics

The integration of AI in the diagnostic isn’t merely a technological upgrade; it’s a paradigm shift aimed at surmounting the inherent limitations of conventional diagnostic procedures. The journey began with machine learning algorithms sifting through colossal datasets to identify patterns and anomalies, setting the stage for a diagnostic revolution.

One of the most profound impacts of AI is manifested in medical imaging. For instance, AI algorithms have shown remarkable proficiency in analyzing radiographic images. A study by Stanford University showcased an AI system that could identify pneumonia on chest X-rays at a level comparable to expert radiologists. This is not an isolated triumph. Across the globe, numerous AI algorithms are being trained to detect a myriad of conditions ranging from diabetic retinopathy to malignant tumors with a precision that often rivals or exceeds human expertise.

Moreover, AI extends its prowess beyond imaging into the realm of predictive analytics, enabling a proactive approach to healthcare. By analyzing a multitude of variables, AI can forecast the onset of certain conditions, providing a window of intervention before the disease progresses to a critical stage.

The sophistication of AI in diagnostics is not just about identifying existing conditions but also unearthing previously undetectable or misunderstood correlations between symptoms, diseases, and treatments. This deeper level of understanding propels healthcare from a reactive to a proactive model, emphasizing prevention over intervention.

Vertex AI: A Ready-to-implement Solution

The healthcare sector’s encounter with Vertex AI reveals a realm of possibilities that extend beyond conventional diagnostic frameworks. This unified ML platform by Google is engineered to amalgamate data engineering, data science, and ML engineering workflows, facilitating a seamless collaboration among teams and accelerating the diagnostic process from data acquisition to actionable insights.

One of the hallmark features of Vertex AI is its capability to augment medical imaging diagnostics. Through AutoML, a feature of Vertex AI, healthcare organizations can train ML models without writing code or preparing data splits, simplifying the deployment of AI in medical imaging diagnostics. This is particularly invaluable in scenarios like analyzing mammograms or CT scans where early detection of anomalies can significantly enhance patient prognosis.

Moreover, Vertex AI’s Custom ML feature provides the flexibility to build and train ML models using proprietary code and data. This facet is crucial for healthcare institutions aiming to tailor ML models to their specific diagnostic needs, potentially unearthing novel diagnostic markers and improving diagnostic accuracy.

The model serving and monitoring features of Vertex AI also ensure that the deployed ML models are optimally functioning in real-time diagnostic settings. This feature ensures that the ML models are up-to-date with the latest data, enhancing the accuracy and reliability of AI-driven diagnostics.

Vertex AI in Diagnostics

The theoretical promises of Vertex AI find tangible expressions in real-world diagnostics. For instance, its collaboration with care.ai to integrate Ambient Intelligent Sensors showcases the potential of AI in creating self-aware, AI-driven healthcare facilities. This venture augments real-time data monitoring and virtual care, enhancing the speed and accuracy of diagnostics, and by extension, the quality of patient care.

Moreover, the early adoption of Vertex AI by leading entities like General Motors and HCA Healthcare underscores its potential in driving digital health forward. While these organizations span different sectors, the common thread is the utilization of Vertex AI to enhance diagnostic processes, whether it’s through improved imaging diagnostics or predictive analytics to forecast patient needs.

Broader Implications of AI for Healthcare

Enhanced diagnostics usher in a new era of personalized patient care, where treatment plans are tailored to individual patient profiles, drastically improving the likelihood of successful outcomes.

Moreover, optimized diagnostic processes significantly reduce the burden on healthcare resources. Faster, more accurate diagnostics mean shorter hospital stays, reduced testing, and timely interventions, all of which contribute to lowering healthcare costs – a benefit that is particularly salient in resource-strapped settings.

Vertex AI, with its suite of ML tools, plays a pivotal role in this broader transformation. By streamlining the diagnostic process, it contributes to a healthcare model that is not only more efficient but also more equitable. The potential for remote diagnostics facilitated by AI can bridge the healthcare divide, ensuring that quality diagnostic services reach underserved and remote populations.

The shift from traditional microscopic diagnostics to advanced AI-driven methods, such as those offered by Vertex AI, represents a major advancement in healthcare. AI is becoming essential in diagnostics, contributing to a healthcare model that is more accurate, proactive, and centered around the patient. Integrating AI with diagnostics is a significant step toward making healthcare more accessible, affordable, and effective.

Further Readings:

Knowledge thats worth delivered in your inbox